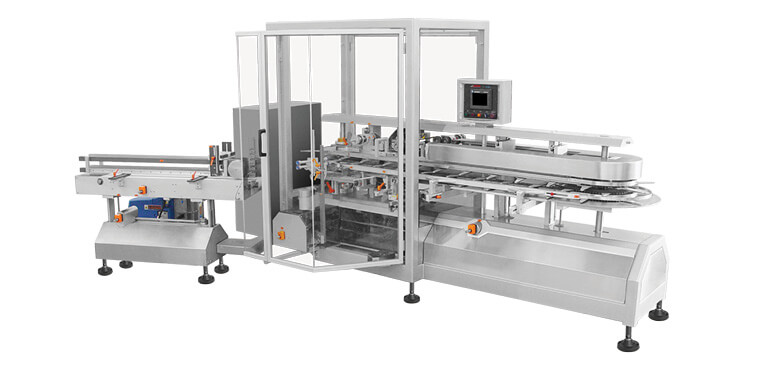

Machines running inserts as part of the packaging process operate at extremely high speeds requiring constant cognizance, observation, and continuous loading, with employees consistently supplying and auditing the process. Existing automated systems contain flaws like requiring operator intervention to open the trays before loading the system, they require extensive changeovers for running different sized inserts, and are difficult to keep running consistently at high speeds. In contrast to these outdated machines, Serpa’s High Speed Insert Feeding System is an innovative solution that reduces operator involvement and creates a streamlined process for an infinite array of inserts.

Streamlined Operations for World-Class Efficiency

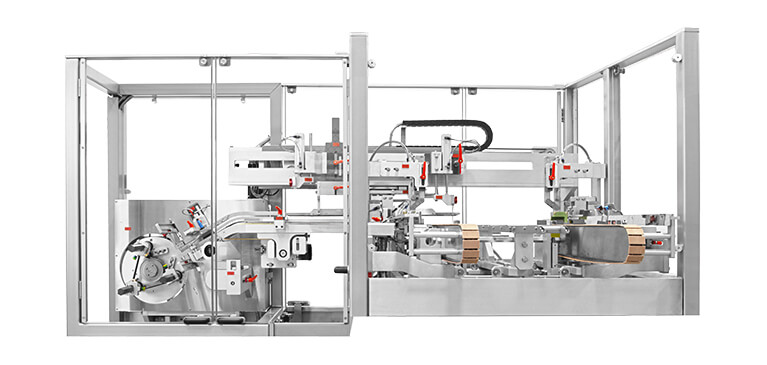

First revealed at Pack Expo International in 2016, Serpa’s patent pending system achieves world-class efficiency by not only reducing required operator intervention, but by solving known issues with existing friction feeders. Before this breakthrough technology hit the market, a major problem required the operator to tear open a flap and hold the inserts in the tray while loading the tray into a vertical magazine. Friction feeders were also tremendously difficult to keep running consistently at high speeds, especially with inserts of various thicknesses and dimensions. The Serpa High Speed Automated Insert Feeding System solves this problem by creating an infeed conveyor where multiple trays of inserts can be loaded and utilizing an empty tray removal process. The inserts are automatically fed into the system and removed from their tray and then transferred to the feeder magazine.

Reduction in Labor and Operator Intervention

In addition, the Serpa High Speed Automated Insert Feeding System operates with an incredibly user-friendly approach minimizing operator involvement, and does not require any trough changeovers to run different tray/insert sizes. Trays are simply loaded onto a horizontal conveyor, then opened for the inserts to be automatically removed and empty trays discharged. A uniquely designed pick and place application works without the resistance of traditional tabbing and instead uses live tabbing and clamping at the insert pick station. This creates an effective means of maintaining control as the insert is 100% contained from pick to destination point.

Advanced Automation Capabilities

In a fast-paced production environment, downtime is costly. Operators need a fast change over with a wide product range to complete production in a compact footprint. The Serpa High Speed Insert Feeding System is the only product on the market that allows insert trays to be loaded onto a horizontal conveyor with automatic removal of the trays from the system without any further operator intervention. Serpa is your only option when a consistent, high-speed, and robust system with the ability to run a variety of inserts is required.

To optimize your insert process flow and implement a lasting solution visit Serpapackaging.com.