The Challenge

A major pharmaceutical company came to Serpa with a very difficult project. They had an application for 12 different sized vials with many different insert combinations in 12 different pack patterns, and they wanted them all to run on one machine. If we could provide the solution, they would buy two machines.

Our Solution

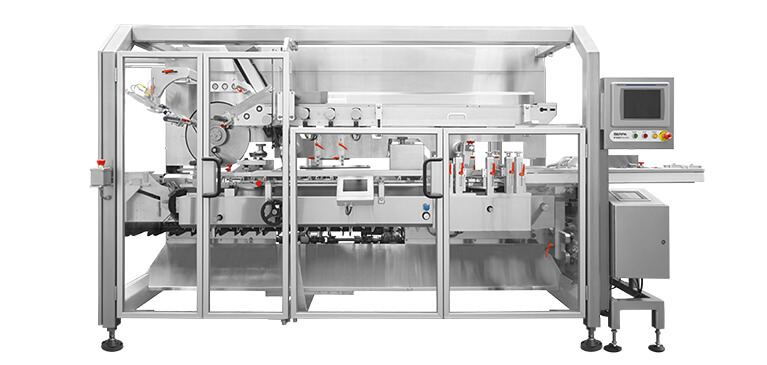

The P100 Balcony Cartoner was the perfect machine for this project. It offers unmatched versatility, easy maintenance, rapid repeatable changeovers and robust construction. Nobody else in the industry could satisfy all of the project requirements with one machine.

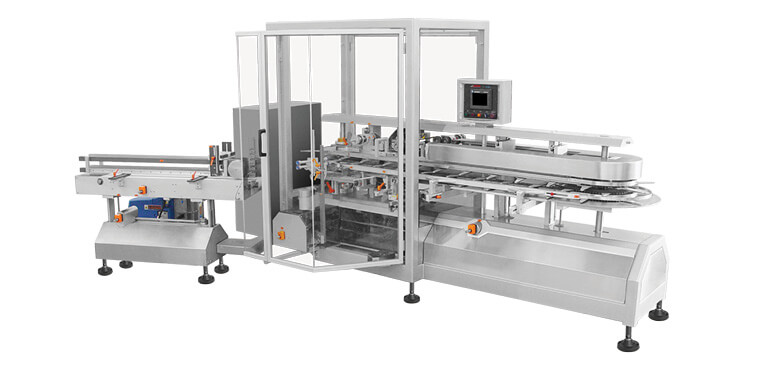

We engineered a custom collation system that was flexible enough to handle all of the different pack patterns. The collator used positive product handling to ensure there was no damage to any of the product. The collator was designed specifically for use with a leaflet feeder.

Vials are side transferred onto the infeed conveyor that takes them to the starwheel transfer which then puts them into the buckets. A second feeding system then optionally places a small bottle into the bucket and a gentle lay down device lays the bottles horizontal into the buckets. A pre-folded leaflet is placed into the bucket gripper and formed into a U fold around the vials during loading. The needles and blister pack are then hand loaded into the bucket. The product is gently loaded and the carton is closed and sealed with hot glue or Tuck and discharged from the machine.