The Challenge

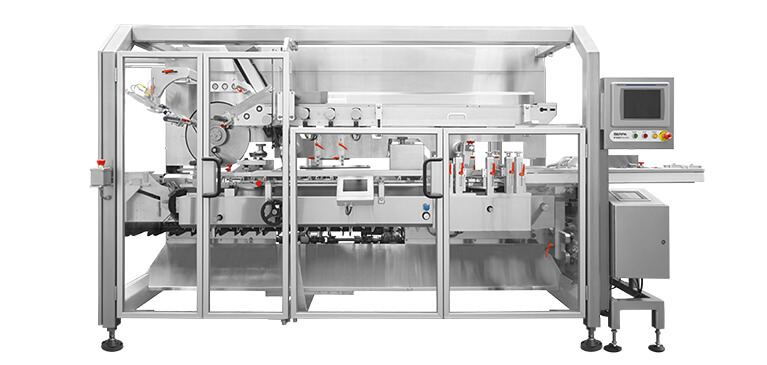

A leading nutraceutical company needed a machine that was capable of packaging both blisters and bottles into cartons. The flexibility of the P100 Balcony Cartoner along with many years of industry experience allowed us to build the perfect solution.

Our Solution

The P100 Balcony Cartoner was the perfect machine for this project. It offers unmatched versatility, easy maintenance, rapid repeatable changeovers and robust construction. It allowed us the flexibility to carton either blisters or bottles with very few change parts.

We engineered a custom collation system that was flexible enough to handle either blister cards or bottles. The collator was designed specifically for use with a leaflet feeder.

Bottles

Bottles were indexed with a timing screw feeding system. A pre-folded leaflet was placed flat in the bucket and the bottles were oriented horizontally into the infeed bucket in time with the leaflet. The product was gently loaded into the cartons which were then closed and sealed with hot glue or tuck closing and discharged from the machine.

Blisters

Blisters were indexed into the buckets with the correct count by a rotary blister card placer. A pre-folded leaflet was placed flat in the bucket in time with the blister card stacks. The product was gently loaded into the cartons which were then closed and sealed with hot glue or tuck closing and discharged from the machine.