Innovation in the snack and health bar industry extends beyond just the products. For example, last year, snack bar manufacturer LivBar challenged its competitors to swap out conventional wrappers for 100% compostable ones. But many snack bar companies are looking to another type of packaging innovation — advances in specialized packing equipment — to help lower costs and improve productivity.

Traditional Packaging Machines Fall Short

Chain Drives: Snack bars can’t easily be side-loaded into their display boxes and are typically loaded from the top. Legacy top-loading packaging machines employ a chain drive that advances products through the packaging process in a straight line. These chain-drive solutions take up a lot of production floor space, and that floor space represents a substantial cost to manufacturers.

Slow Reconfiguring Process: As well, reconfiguring chain-based machines to accept new packaging requirements is a slow, ‘hands-on’ process involving multiple chain adjustments and parts replacement. The resulting downtime costs— often significant — quickly rack up for high-volume snack bar producers.

Maintenance Downtime: Maintaining those chain drives only adds to the downtime problem. Chains must be frequently inspected and serviced, and also replaced at regular intervals — sometimes leaving machines offline for days.

Shorter Lifespan: Finally, custom packaging equipment represents a substantial capital investment. Chain-based machines are expensive and difficult to retrofit for new product packaging needs, limiting their effective lifespan and shortening the amortization time for these costly capital assets.

New Technology Cuts Costs, Improves Uptime

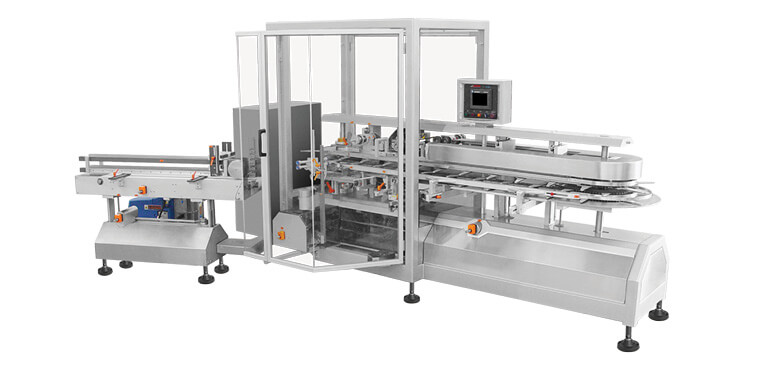

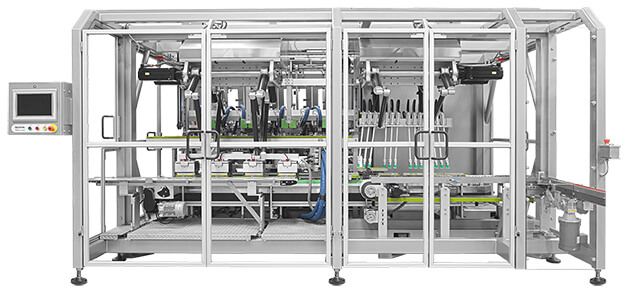

Here at Serpa, our high-speed FG4 top load cartoner is engineered to address the shortcomings of traditional packaging machines, providing snack bar producers, packaged food manufacturers, and pharmaceutical companies with a more flexible, cost-effective solution.

Built on Rockwell Automation’s Magnemotion® platform, the FG4 features independent cart technology (ICT). By replacing the chain drive with magnetically propelled movers using advanced linear motors, the FG4 can change the pitch and spacing of the ‘buckets’ on the line, increasing throughput (up to 200 cartons per minute) and providing a wide range of flexible configuration options. These capabilities often eliminate the need for additional machines to handle heavy production loads.

By replacing the chain drive with ICT, we are able to build the FG4 in a small footprint circular configuration, minimizing space requirements, and significantly lowering operating costs.

Designed for ease of use and to promote safe operation, the FG4 allows complete access from the operator side of the machine and employs full height guard doors. All changeover points are easily accessible, and the FG4 meets all sanitary requirements and FDA standards.

The FG4 also employs an icon-based, menu-driven system operating system. This powerful, operator-friendly system is used across all of Serpa’s ICT-based solutions, simplifying operator training.

Taking Aim at Downtime

This operating system, combined with the use of ICT, has transformed the changeover process for our food manufacturing customers. Legacy packaging solutions require precise, time-consuming chain adjustments to transition from one product line to the next. With the FG4, however, operators simply download each new packaging configuration into the machine, and the Magnemotion movers align themselves. By eliminating the need for tools and manual adjustments, the FG4 can often be ready to begin packaging in less than 15 minutes — as opposed to hours of downtime for traditional packaging solutions.

Eliminating the chain drive also has a significant impact on service downtime. With minimal drive components and no chain maintenance or replacement required, the FG4 is almost always up and running. Backed by our ’98% uptime’ guarantee, this benefits our customers both financially and operationally.

It Starts – And Ends – With Service

While the FG4 top load cartoner delivers compelling advantages over its legacy counterparts, it takes more than just an excellent machine to meet the demanding business requirements of our customers.

At Serpa, we take a ‘full lifecycle’ approach to designing, implementing, and supporting our packaging solutions. Each machine is custom-configured based on unique customer requirements and undergoes exhaustive factory acceptance testing. Before they leave our facility, we strive to ensure every Serpa solution works with 100% efficiency when installed.

We also place a lot of emphasis on the speed of our installations. Our techs work hard to get our machines up and running quickly — much faster than the industry average.

That philosophy — going the extra mile — is key to how we approach service and maintenance. Rather than offering a standard 24-hour callback, Serpa provides a guaranteed one-hour response. We support a range of service plans, all designed to keep our clients up and running. With many of our customers operating three shifts around the clock at full capacity, exceptional service isn’t just nice to have — their businesses depend on it.

Finally, we build our FG4 — and all of our packaging solutions — for durability. We design them to minimize maintenance costs and maximize lifespan, and to operate trouble-free for years, even decades, if necessary. Serpa supports every machine we’ve ever built, even those resold in the secondary market. And that’s our reputation — our customers know that we stand behind everything we make.

“I’m proud that we’ve been in business since 1985 — over 34 years — and we still support every machine we’ve ever made. Service is what makes Serpa who we are.”

Fernando Serpa, President