Thermoformed blisters are a popular packaging type. During the blister production process, heat is applied to soften the plastic, and the pliable plastic arrives in a forming station where pressure forms the blister cavity into a negative mold. Unfortunately, when the plastic cools, it curls, making it difficult to handle in a magazine and hard to deliver to a cartoner. Heretofore, feeding systems required spinning wheels or disks to separate the blister packs and drop them into the cartoner infeed bucket—often causing jamming or product miscounts. Most of the innovations surrounding these feeding system glitches have been based around the material, not the process, and the issue has gone unresolved.

Until now.

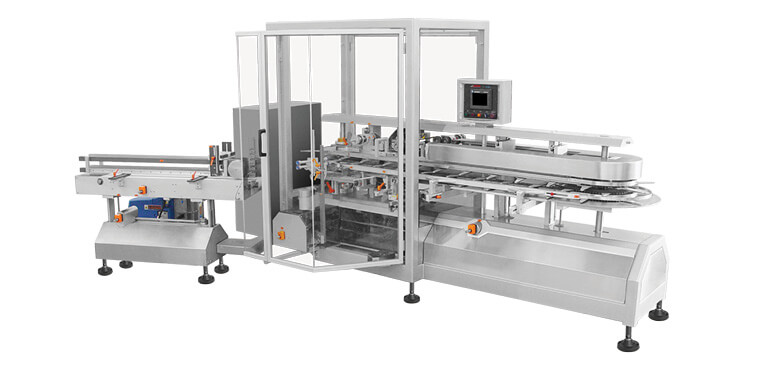

Serpa’s new blister feeding system is the first on the market that solves these issues. The new system utilizes a combination of assemblies to handle blisters positively, from the beginning when they are added to the magazine, all the way to placement into the cartoner infeed bucket.

Here’s how:

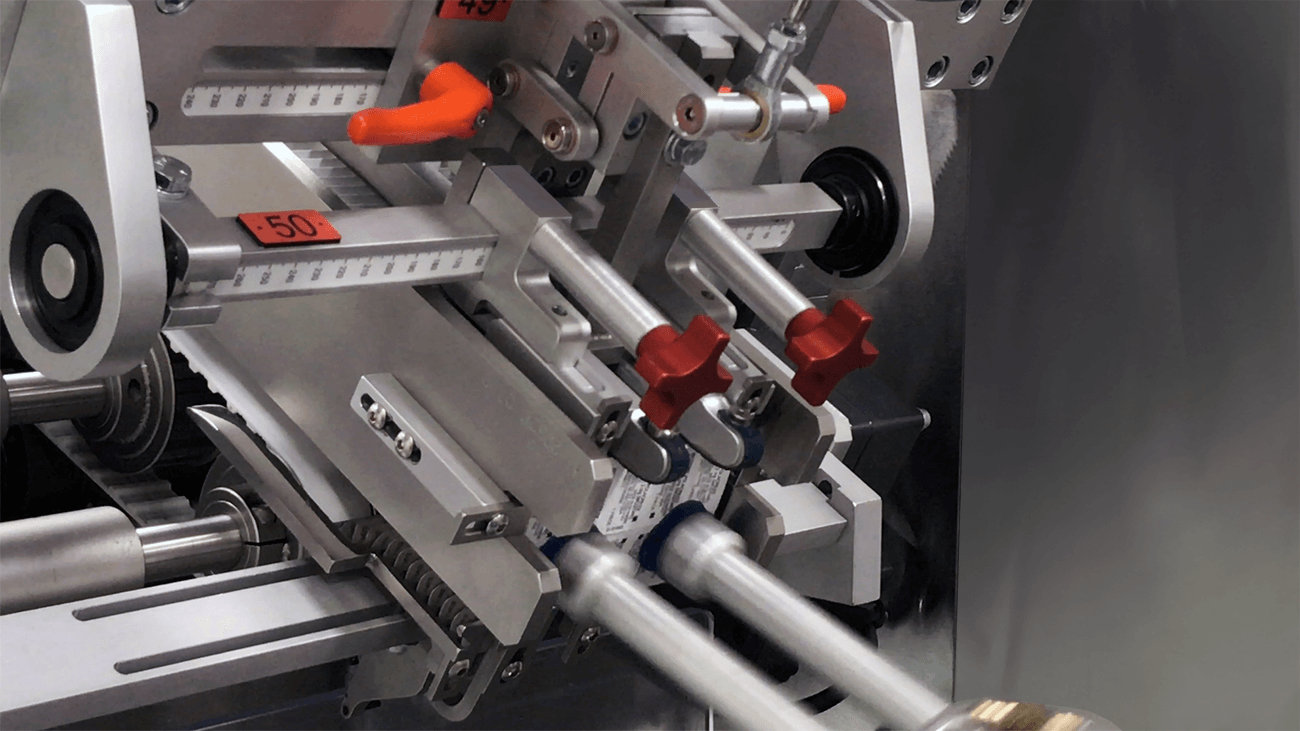

An operator places the blisters into the powered horizontal magazine which transfers them to the blister pick station. The blister pick station includes overhead live tabbing for releasing and overhead blister clamping for engaging, as well as static bottom and side tabbing. An orbital vacuum pick and place assembly then plucks the blister from the magazine pick station, and places it in the cartoner infeed bucket, with individual placement timing controlled by the cartoner.

In addition, there are several options available within the system. For example, a gravity magazine can replace the powered horizontal magazine. Or, as opposed to the orbital vacuum pick assembly, a rotary vacuum pick assembly might be used for higher speeds. Further, since the system was designed for flexibility it can be customized for many different types of products.

This system has many applications and solves most of the problems faced where there is an opportunity for damage during blister feeding. View a video of this patent-pending solution today!